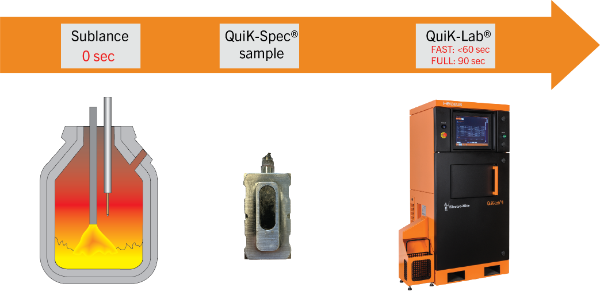

Direct Analysis Measurement Technology

Fast Converter Sample Analysis

The main aim of the converter process is to get the temperature and carbon within specifications and to reduce the amount of phosphorus at the end of blowing. Until now, because of steel grades with tighter specifications on phosphorus and also increased phosphorus content in iron ore, steel makers have been waiting for the final sample (TSO measurement with sublance) to know the phosphorus content before deciding if they need to reblow the heat or can tap it immediately.

QuiK-Lab offers the potential to analyze phosphorus within 80 seconds of the TSC inblow measurements. This offers operators critical information on the P flight path and they can continue the oxygen blow until all the critical elements and the temperature are within specification. QuiK-Lab and QuiK-Spec enable to reduce the converter tap-to-tap time by a few minutes and increase the productivity of the convertor shop.