즉각적인 분석을 위한 중요한 연결 고리인 QuiK-Spec® 및 QuiK-Lab®

인 수치를 낮추고 CO2 배출량을 줄이면서 고품질의 강철을 생산해야 한다는 요구가 증가함에 따라 철강 공장은 컨버터(전로) 공정을 완전히 새롭게 구상해야 합니다. 공정 중 강철(용강) 성분을 빠르게 파악하는 것이 핵심입니다.

Heraeus Electro-Nite의 QuiK-Lab® 스펙트럼 장치는 컨버터(전로) 처리 중 침지 후 1분 이내에 탄소, 인, 망간 및 황과 같은 가장 중요한 원소를 빠르고 안정적으로 분석할 수 있습니다.

- 블로잉이 끝나기 전에 액체 강철(용강)의 구성 성분에 대한 모든 중요한 정보가 제공됩니다.

- 운영자가 온도, 탄소, 인을 규격에 적합하도곡 만들기 위해 취해야 할 조치를 결정하도록 지원합니다.

- 리블로우와 오버블로우를 최소화합니다.

- 컨버터(전로)의 탭 투 탭 시간을 몇 분으로 단축하고 컨버터 작업장의 생산성을 높입니다.

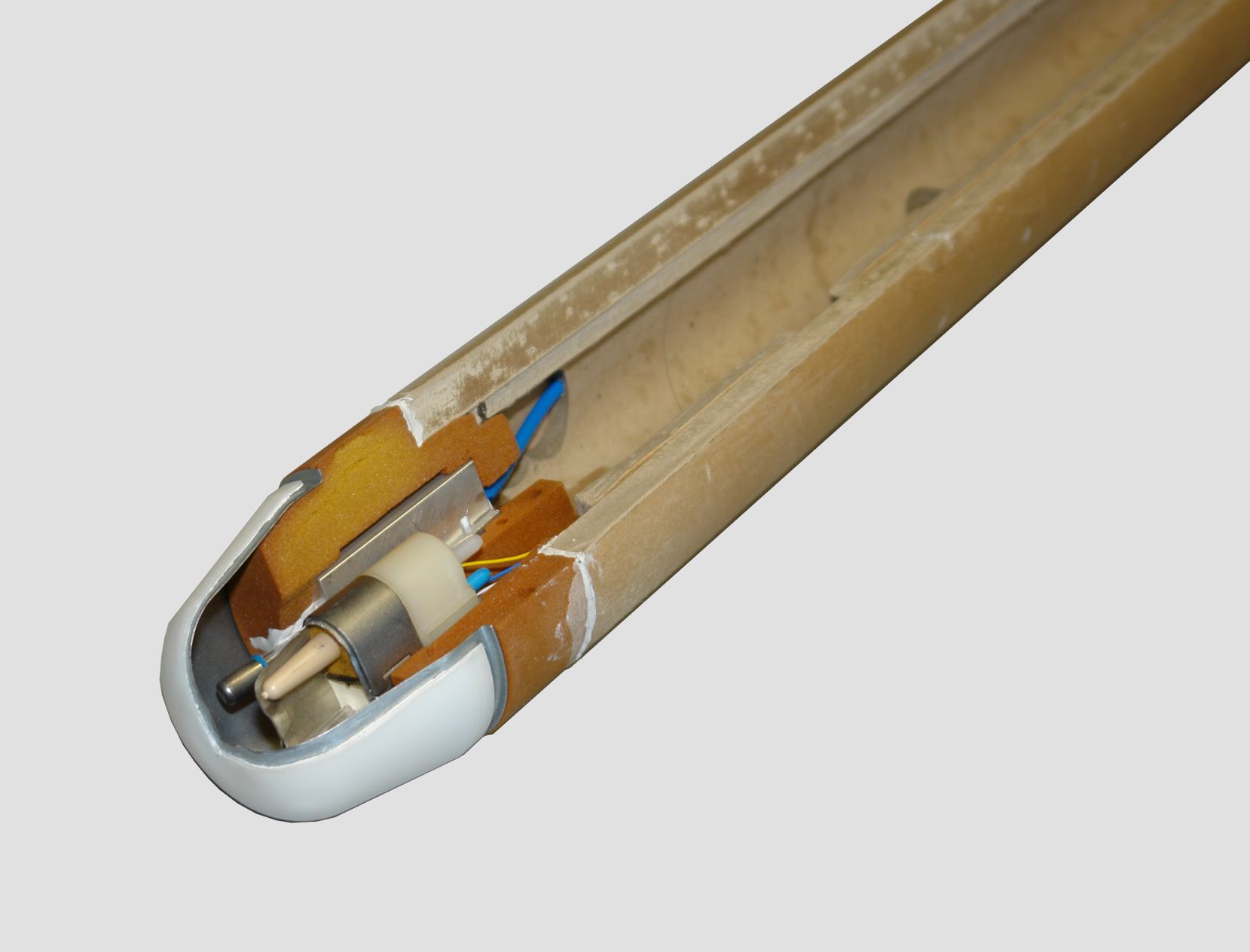

전처리 없는 청정한 샘플 제공

- 질소 또는 아르곤 가스 퍼징 기술을 통해 가능

- 고유한 샘플 디자인

올바른 유형의 프로브를 선택할 수 있는 유연성과 자율성

- TSC-TSO 프로브와 QuiK-Spec® 프로브를 모두 사용하는 새로운 하드웨어 측정 방법

서브랜스 기술은 새로운 Multi-Lance® QuiK-Spec®과 함께 기존 Multi-Lance® 센서와 동일하게 온도, 산소 및 액체를 측정합니다.

기술 데이터

|

Item |

Description |

|---|---|

| Measurement application | Element composition (C, Mn, S, P, Al, V, Cr, Si, Mo, Ni, Co, Cu, Nb, Ti, Sn, As, Ca, B, Mg, Zr) of QuiK-Spec® samples (QSS) |

| Analysis time | 85 sec with 2 sparks |

| Display resolution | 0.0001 |

| Display units | wt%, ppm, pts |

| Voltage/Frequency | 1 Ph 100-240VAC 50/60Hz; Power (operational, peak): unknown; Power (operational, heating): <640W@230 V, <320W@110 V; Currency (operational): < 10A@230, < 16 A @110 Volt ; Short circuit current rating: < 20 kVA |

| Fuse | Slow blow fuse |

| Argon | 6,8 bar max; lab quality (min 5.0); consumption 2 l/min between measurements and <5,8SL/min during measurements. |

| Ambiant operating temperature | -20 ºC to 50 ºC (-4 °F to 122 °F) 1 |

| Operating humidity range | between 5% and 90% (at 20ºC or 68°F) 2 |

| Storage conditions | between -20°C and 70°C (-4 °F and 158 °F) with a maximum of 90% non condensing RH |

| Dimensions | 850 x 750x 1830 mm (length, width, height) |

| Weight | 620 kg |

1 To ensure optimal performance at cold temperatures we have mounted on the internal heatsink four 160W PTC heaters (HP06-2/15-240) (together 160W at 230V, 146W at 110V) per heater. The heaters will heat up the cabinet and electronics until the temperature is high enough to start the IPC and the .NET script safely. During this pre-heating the pre-heating light will light up.

2 In high humidity conditions small amounts of condensation can be formed on the internal heatsink. Underneath this heatsink there is a drain reservoir and flexible tubing to lead water to the outside of the cabinet