Our Impact

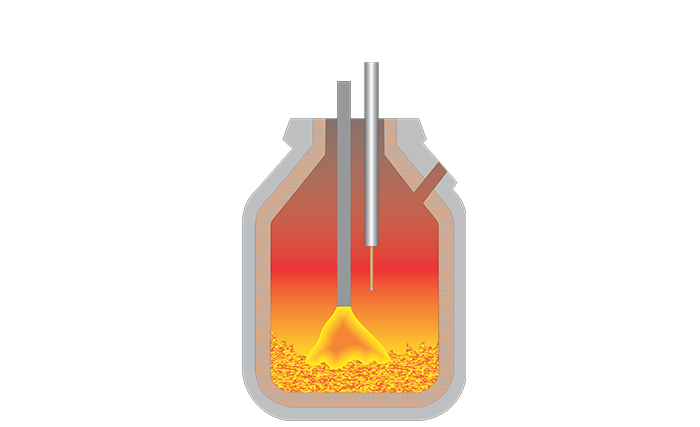

People working with molten metal need maximum process control.

With our innovative products and solutions, they can measure and manage with speed and precision, minimizing lost production, optimizing energy use, and increasing automation. This results directly in enhanced worker safety, greater operational efficiency and significantly reduced environmental impact. That is how our solutions have a direct and significant impact on the sustainability goals of our customers. And that is why we keep working towards a more sustainable and responsible industrial landscape through continuous innovation and collaboration.

Achieve Maximum Efficiency and Reduction of CO2 Emissions

Celox®, Multi-Lance®, QuiK-Spec® and QuiK-Lab®

Temperature Control

Save energy and reduce CO2 emissions with our products, by accurately measuring temperature and controlling energy consumption per heat and tap-to-tap time.

Chemical Composition Monitoring

Our solutions, such as QuiK-Spec® and QuiK-Lab®, enable fast and safe sampling of representative samples, resulting in improved process efficiency, energy savings and reduced CO2 emissions.

Process Optimization

Utilize our Multi-Lance® sensors and the QuiK-Spec® and QuiK-Lab® system to measure temperature, carbon, and chemical composition during the in-blow and end-blow process, improving efficiency and reducing CO2 emissions.

Control and Reduction of Alloy Consumption

Our Hot Metal Celox Si and S sensors provide accurate measurements of silicon and sulfur, enabling optimal charge balance and reducing alloy consumption. This improves process control and decreases consumption of DeS agent while saving time with quick sulfur analysis.

Case Studies

Learn more about the sustainability impact of our solutions in our selected case studies.

- AI-Driven Temperature Control in Secondary Metallurgy Based on Continuous Temperature Measurement

Joint paper with SST & Çolakoğlu, published in the July 2025 issue of Iron & Steel Technology

- CELSA Group Green Steel: Every degree counts

- Bath Level Management in the Consteel DC EAF

- Controlling of EAF Process via Chameleon, Optic Fibre Measurement

- Instant Analysis of Phosphorus Content with Quik-Spec® & Quik-Lab®

- Increasing of LF Performance by Controlling the Slag and Steel Oxygen Activities

- The Importance of Measuring Hydrogen in Steel Production for Sustainable Practices