Foundry Software

In the modern foundry world, automated gathering of process data, and linking them, is becoming increasingly important in order to introduce reliable process control and monitoring.

Through these means, a stable and low-scrap process can be established.

To ensure this, the use of foundry-optimised software is essential.

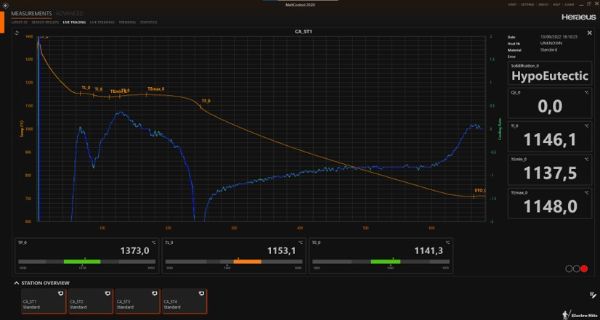

MeltControl Foundry is a digital analysis and data visualisation tool for melt quality control. It logs and displays real-time measurement curves from Electro-Nite measurement instruments (QuiK-Lab® E, Digitemp® E, Digilance, Celox® Foundry, ...). For the instruments that support the transmission of curve data, MeltControl Foundry also shows and stores the curves. Measurement curves are displayed live during a measurement so that the quality of the melt can be easily and quickly checked. Measurement curves can also be displayed after a measurement from the database, allowing an overview of melting performance over time. Using the MeltControl Foundry system, all measurements from the melt can be logged and incorporated into the foundry process control system (ex: Foundry Navigator).

The MeltControl Foundry system consists of local measuring instruments and one or more PCs. Up to 10 clients can be connected to the MeltControl Foundry server so that more than one user can use the application at the same time.

Thermal Analysis features:

- Measurement of TLiq, CEL, %C, %Si, DT, DTM, SF1, SF2

- Cooling pattern Hypoeutectic, Eutectic, Hypereutectic

- Recommendation of alloy additions to correct to target value

- Material ranges with colour code for in/ out of range values

- Formulas, trending and alerts